| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Acetone

CAS:67-64-1 |

|

|

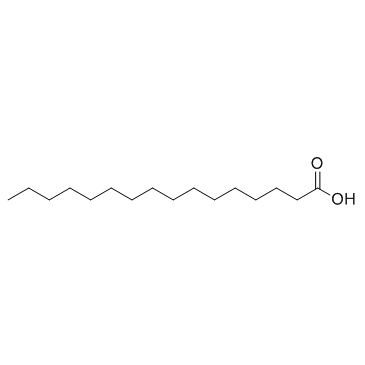

Palmitic acid

CAS:57-10-3 |

|

|

DL-Lysine

CAS:70-54-2 |

|

|

Lactulose

CAS:4618-18-2 |

|

|

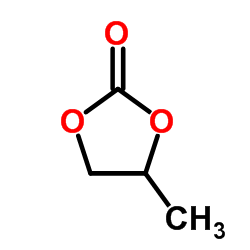

Propylene carbonate

CAS:108-32-7 |