| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Sulfuric acid

CAS:7664-93-9 |

|

|

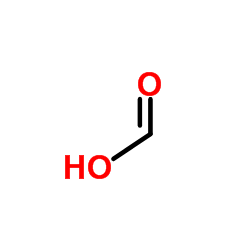

Formic Acid

CAS:64-18-6 |

|

|

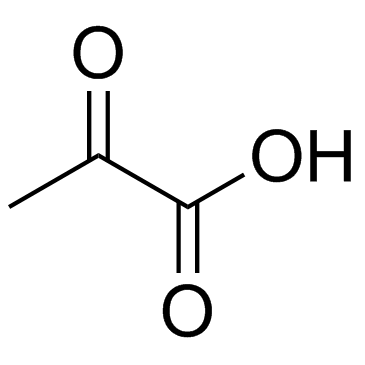

Pyruvic acid

CAS:127-17-3 |

|

|

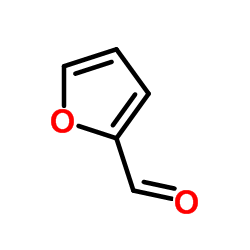

Furfural

CAS:98-01-1 |

|

|

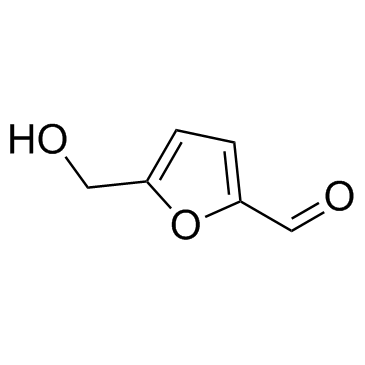

5-hydroxymethylfurfural

CAS:67-47-0 |