| Structure | Name/CAS No. | Articles |

|---|---|---|

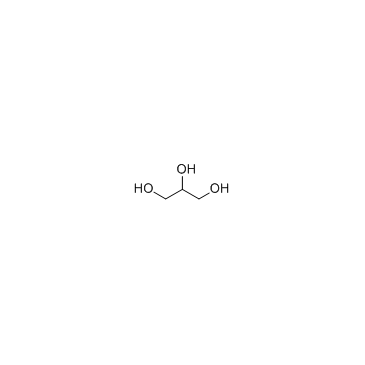

|

Glycerol

CAS:56-81-5 |

|

|

Sulfuric acid

CAS:7664-93-9 |

|

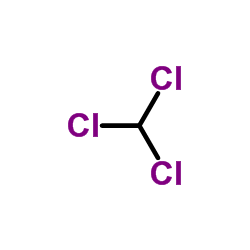

|

Chloroform

CAS:67-66-3 |

|

|

Hydrochloric acid

CAS:7647-01-0 |

|

|

Sodium hydroxide

CAS:1310-73-2 |

|

|

Ethanol

CAS:64-17-5 |

|

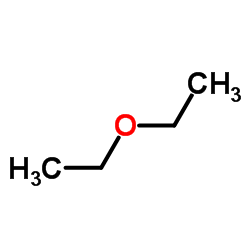

|

Diethyl ether

CAS:60-29-7 |

|

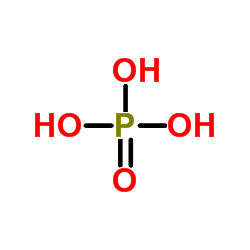

|

Phosphoric acid

CAS:7664-38-2 |

|

|

Methanol

CAS:67-56-1 |

|

|

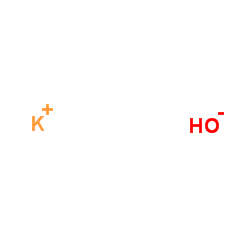

Potassium hydroxide

CAS:1310-58-3 |