9003-56-9

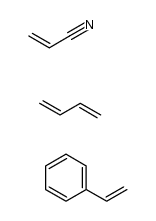

| 中文名 | 聚(丙烯腈-co-丁二烯-co-苯乙烯) |

|---|---|

| 英文名 | ABS Resins |

| 中文别名 |

丙烯腈-丁二烯-苯乙烯三元共聚物(阻燃)

ABS 树脂 ABS树脂 |

| 英文别名 |

abscopolymer

NITRILERUBBERCOPOLYMERS ABSPOLYMERS abs KRYLENE ABSPOLYMER MFCD00133993 absresin absresins ABS rod Transparent ABS |

| 密度 | 1.05 g/mL at 25ºC |

|---|---|

| 沸点 | 145.2ºC at 760 mmHg |

| 熔点 | 58.54(±0.5)ºC |

| 分子式 | (C8H8.C4H6.C3H3N)x |

| 分子量 | 211.30200 |

| 精确质量 | 211.13600 |

| PSA | 23.79000 |

| LogP | 4.38398 |

| 外观性状 | 白色 |

| 储存条件 | 密闭于阴凉干燥环境中 |

| 稳定性 | 遵照规定使用和储存则不会分解。 |

| 水溶解性 | acetone, MEK and DMF: soluble |

| 分子结构 | 1、摩尔折射率:无可用 2、 摩尔体积(cm3/mol):无可用 3、 等张比容(90.2K):无可用 4、 表面张力(dyne/cm):无可用 5、 极化率:无可用 |

| 计算化学 | 1.疏水参数计算参考值(XlogP):无 2.氢键供体数量:0 3.氢键受体数量:1 4.可旋转化学键数量:2 5.互变异构体数量:无 6.拓扑分子极性表面积23.8 7.重原子数量:16 8.表面电荷:0 9.复杂度:144 10.同位素原子数量:0 11.确定原子立构中心数量:0 12.不确定原子立构中心数量:0 13.确定化学键立构中心数量:0 14.不确定化学键立构中心数量:0 15.共价键单元数量:3 |

| 更多 | 1. 性状:微黄色 2. 密度(g/mL,25/4℃):1.05 3. 相对蒸汽密度(g/mL,空气=1):无可用 4. 熔点(ºC):58.54(±0.5)℃ 5. 沸点(ºC,常压):无可用 6. 沸点(ºC,5.2kPa):无可用 7. 折射率:无可用 8. 闪点(ºC):无可用 9. 比旋光度(º):无可用 10. 自燃点或引燃温度(ºC):无可用 11. 蒸气压(kPa,25ºC):无可用 12. 饱和蒸气压(kPa,60ºC):无可用 13. 燃烧热(KJ/mol):无可用 14. 临界温度(ºC):无可用 15. 临界压力(KPa):无可用 16. 油水(辛醇/水)分配系数的对数值:无可用 17. 爆炸上限(%,V/V):无可用 18. 爆炸下限(%,V/V):无可用 19. 溶解性:溶于冷水,其水溶液呈酸性。 |

Synonym:2-Propenitrile, polymer with 1,3-butadiene and ethenylbenzene Section 2 - COMPOSITION, INFORMATION ON INGREDIENTS

Risk Phrases: 20/21/22 45 Section 3 - HAZARDS IDENTIFICATION EMERGENCY OVERVIEW

Harmful by inhalation, in contact with skin and if swallowed. May cause cancer. Potential Health Effects Eye: May cause eye irritation. The toxicological properties of this material have not been fully investigated. Skin: May cause skin irritation. The toxicological properties of this material have not been fully investigated. Ingestion: May cause gastrointestinal irritation with nausea, vomiting and diarrhea. The toxicological properties of this substance have not been fully investigated. Inhalation: May cause respiratory tract irritation. The toxicological properties of this substance have not been fully investigated. Chronic: No information found. Section 4 - FIRST AID MEASURES Eyes: Flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical aid immediately. Skin: Get medical aid. Flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Wash clothing before reuse. Ingestion: If victim is conscious and alert, give 2-4 cupfuls of milk or water. Never give anything by mouth to an unconscious person. Get medical aid immediately. Wash mouth out with water. Inhalation: Remove from exposure and move to fresh air immediately. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical aid. Notes to Physician: Section 5 - FIRE FIGHTING MEASURES General Information: As in any fire, wear a self-contained breathing apparatus in pressure-demand, MSHA/NIOSH (approved or equivalent), and full protective gear. During a fire, irritating and highly toxic gases may be generated by thermal decomposition or combustion. Vapors may be heavier than air. They can spread along the ground and collect in low or confined areas. Extinguishing Media: Use agent most appropriate to extinguish fire. Use water spray, dry chemical, carbon dioxide, or appropriate foam. Section 6 - ACCIDENTAL RELEASE MEASURES General Information: Use proper personal protective equipment as indicated in Section 8. Spills/Leaks: Forms smooth, slippery surfaces on floors, posing an accident risk. Clean up spills immediately, observing precautions in the Protective Equipment section. Sweep up or absorb material, then place into a suitable clean, dry, closed container for disposal. Provide ventilation. Section 7 - HANDLING and STORAGE Handling: Wash thoroughly after handling. Use with adequate ventilation. Avoid contact with eyes, skin, and clothing. Keep container tightly closed. Avoid ingestion and inhalation. Storage: Store in a tightly closed container. Store in a cool, dry, well-ventilated area away from incompatible substances. Section 8 - EXPOSURE CONTROLS, PERSONAL PROTECTION Engineering Controls: Use adequate ventilation to keep airborne concentrations low. Exposure Limits CAS# 9003-56-9: Personal Protective Equipment Eyes: Wear appropriate protective eyeglasses or chemical safety goggles as described by OSHA's eye and face protection regulations in 29 CFR 1910.133 or European Standard EN166. Skin: Wear appropriate protective gloves to prevent skin exposure. Clothing: Wear appropriate protective clothing to prevent skin exposure. Respirators: Follow the OSHA respirator regulations found in 29 CFR 1910.134 or European Standard EN 149. Use a NIOSH/MSHA or European Standard EN 149 approved respirator if exposure limits are exceeded or if irritation or other symptoms are experienced. Section 9 - PHYSICAL AND CHEMICAL PROPERTIES Physical State: Solid Color: Not available. Odor: Not available. pH: Not available. Vapor Pressure: Not available. Viscosity: Not available. Boiling Point: Not available. Freezing/Melting Point: Not available. Autoignition Temperature: Not applicable. Flash Point: Not applicable. Explosion Limits, lower: N/A Explosion Limits, upper: N/A Decomposition Temperature: Solubility in water: insoluble Specific Gravity/Density: Molecular Formula: C15H17N1x Molecular Weight: 197.119 Section 10 - STABILITY AND REACTIVITY Chemical Stability: Stable under normal temperatures and pressures. Conditions to Avoid: Dust generation. Incompatibilities with Other Materials: Oxidizing agents. Hazardous Decomposition Products: Carbon monoxide, irritating and toxic fumes and gases, carbon dioxide. Hazardous Polymerization: Has not been reported Section 11 - TOXICOLOGICAL INFORMATION RTECS#: CAS# 9003-56-9: AT6970000 LD50/LC50: Not available. Carcinogenicity: Poly(acrylonitrile-butadiene-styrene) - Not listed by ACGIH, IARC, or NTP. Other: See actual entry in RTECS for complete information. Section 12 - ECOLOGICAL INFORMATION Section 13 - DISPOSAL CONSIDERATIONS Dispose of in a manner consistent with federal, state, and local regulations. Section 14 - TRANSPORT INFORMATION IATA Not regulated as a hazardous material. IMO Not regulated as a hazardous material. RID/ADR Not regulated as a hazardous material. Section 15 - REGULATORY INFORMATION European/International Regulations European Labeling in Accordance with EC Directives Hazard Symbols: T Risk Phrases: R 45 May cause cancer. R 20/21/22 Harmful by inhalation, in contact with skin and if swallowed. Safety Phrases: S 53 Avoid exposure - obtain special instructions before use. S 28A After contact with skin, wash immediately with plenty of water. S 37 Wear suitable gloves. S 45 In case of accident or if you feel unwell, seek medical advice immediately (show the label where possible). WGK (Water Danger/Protection) CAS# 9003-56-9: No information available. Canada CAS# 9003-56-9 is listed on Canada's DSL List. CAS# 9003-56-9 is not listed on Canada's Ingredient Disclosure List. US FEDERAL TSCA CAS# 9003-56-9 is listed on the TSCA inventory. SECTION 16 - ADDITIONAL INFORMATION N/A |

|

生态学数据: 该物质对环境可能有危害,对水体应给予特别注意。 CHEMICAL IDENTIFICATION

|

| 危害码 (欧洲) | Xn |

|---|---|

| 风险声明 (欧洲) | R20/21/22;R36/37/38 |

| 安全声明 (欧洲) | S36-S26 |

| 危险品运输编码 | NONH for all modes of transport |

| WGK德国 | 3 |

| RTECS号 | AT6970000 |