Monitoring bioreactors using principal component analysis: production of penicillin G acylase as a case study.

Edson Romano Nucci, Antonio J G Cruz, Roberto C Giordano

Index: Bioprocess Biosyst. Eng. 33(5) , 557-64, (2010)

Full Text: HTML

Abstract

The complexity of biological processes often makes impractical the development of detailed, structured phenomenological models of the cultivation of microorganisms in bioreactors. In this context, data pre-treatment techniques are useful for bioprocess control and fault detection. Among them, principal component analysis (PCA) plays an important role. This work presents a case study of the application of this technique during real experiments, where the enzyme penicillin G acylase (PGA) was produced by Bacillus megaterium ATCC 14945. PGA hydrolyzes penicillin G to yield 6-aminopenicilanic acid (6-APA) and phenyl acetic acid. 6-APA is used to produce semi-synthetic beta-lactam antibiotics. A static PCA algorithm was implemented for on-line detection of deviations from the desired process behavior. The experiments were carried out in a 2-L bioreactor. Hotteling's T(2) was the discrimination criterion employed in this multivariable problem and the method showed a high sensibility for fault detection in all real cases that were studied.

Related Compounds

| Structure | Name/CAS No. | Molecular Formula | Articles |

|---|---|---|---|

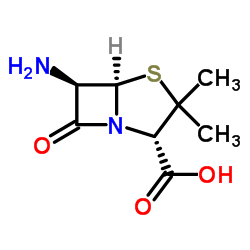

|

6-Aminopenicillanic acid

CAS:551-16-6 |

C8H12N2O3S |

|

Enhanced production of 6-aminopenicillanic acid in aqueous m...

2010-01-01 [Prep Biochem Biotechnol. 40(1) , 38-45, (2010)] |

|

Synthesis and biological evaluation of penem inhibitors of b...

2009-07-15 [Bioorg. Med. Chem. Lett. 19(14) , 3787-90, (2009)] |

|

FT-IR, FT-Raman, ab initio and DFT structural and vibrationa...

2010-01-01 [Spectrochim. Acta. A. Mol. Biomol. Spectrosc. 75(1) , 183-90, (2010)] |

|

One-pot, two-step enzymatic synthesis of amoxicillin by comp...

2010-09-01 [Appl. Microbiol. Biotechnol. 88(1) , 49-55, (2010)] |

|

Small molecule inhibition of a Group II chaperonin: pinpoint...

2009-01-01 [Arch. Biochem. Biophys. 481(1) , 45-51, (2009)] |