| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Sodium hydroxide

CAS:1310-73-2 |

|

|

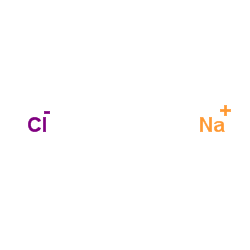

sodium chloride

CAS:7647-14-5 |

|

|

Hydrochloric acid

CAS:7647-01-0 |

|

|

Methanol

CAS:67-56-1 |

|

|

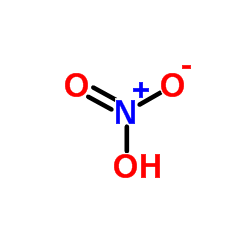

nitric acid

CAS:7697-37-2 |

|

|

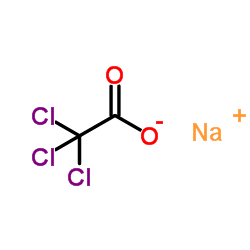

Sodium TCA

CAS:650-51-1 |

|

|

3-Ethyl-2,4-pentanedione

CAS:1540-34-7 |

|

|

4-Aminoantipyrine

CAS:83-07-8 |

|

|

SODIUM CHLORIDE-35 CL

CAS:20510-55-8 |

|

|

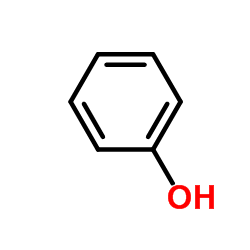

Phenol

CAS:108-95-2 |