| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Acetone

CAS:67-64-1 |

|

|

Sodium hydroxide

CAS:1310-73-2 |

|

|

Ethanol

CAS:64-17-5 |

|

|

3-Ethyl-2,4-pentanedione

CAS:1540-34-7 |

|

|

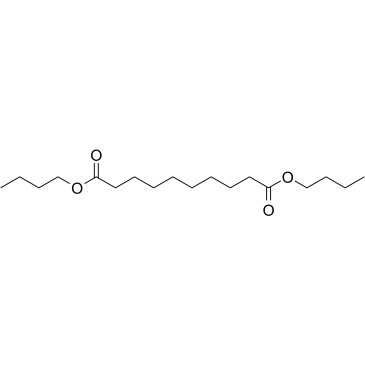

Dibutyl sebacate

CAS:109-43-3 |

|

|

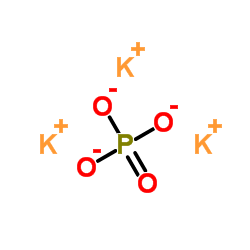

Potassium phosphate

CAS:7778-53-2 |