| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Sulfuric acid

CAS:7664-93-9 |

|

|

Ethanol

CAS:64-17-5 |

|

|

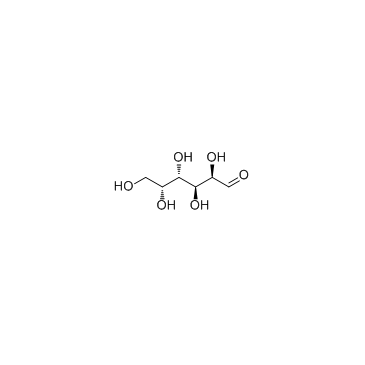

D-(+)-Glucose

CAS:50-99-7 |

|

|

calcium dihydroxide

CAS:1305-62-0 |

|

|

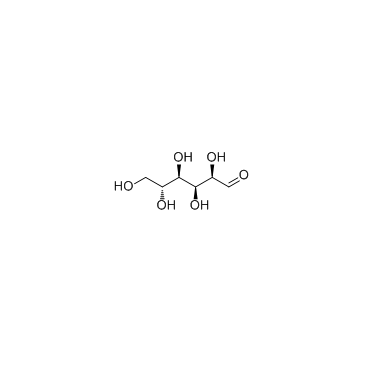

D-Galactose

CAS:59-23-4 |

|

|

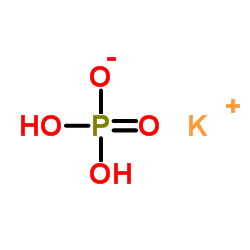

Monopotassium phosphate

CAS:7778-77-0 |

|

|

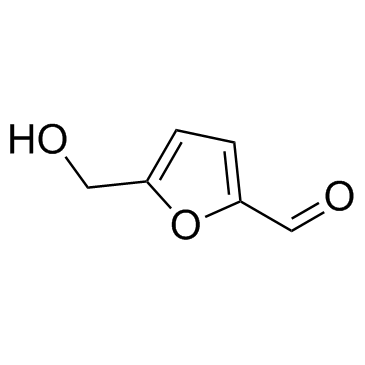

5-hydroxymethylfurfural

CAS:67-47-0 |