| Structure | Name/CAS No. | Articles |

|---|---|---|

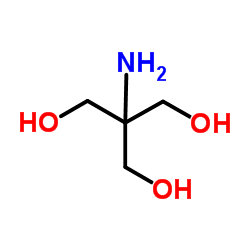

|

Trometamol

CAS:77-86-1 |

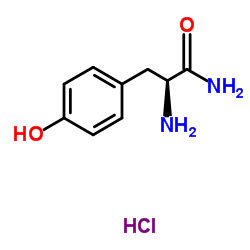

|

|

H-Tyr-NH2

CAS:4985-46-0 |