| Structure | Name/CAS No. | Articles |

|---|---|---|

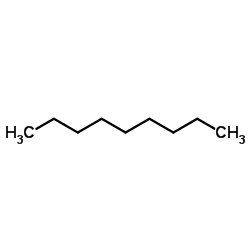

|

Nonane

CAS:111-84-2 |

|

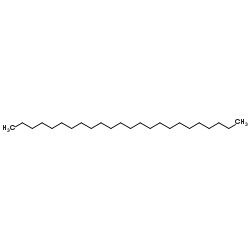

|

Tetracosane

CAS:646-31-1 |