| Structure | Name/CAS No. | Articles |

|---|---|---|

|

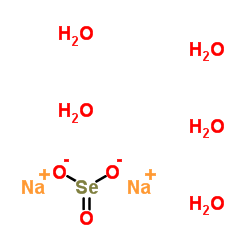

Sodium selenite hydrate (2:1:5)

CAS:26970-82-1 |

|

|

Sodium selenite

CAS:10102-18-8 |

|

|

sodium,hydrogen selenite

CAS:7782-82-3 |