| Structure | Name/CAS No. | Articles |

|---|---|---|

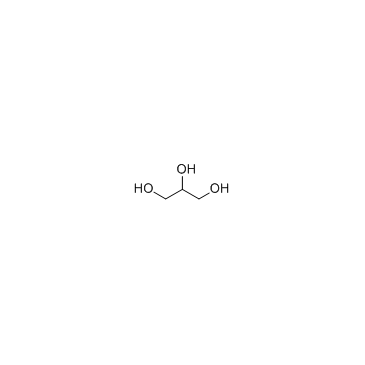

|

Glycerol

CAS:56-81-5 |

|

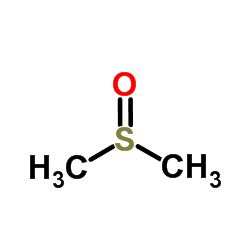

|

Dimethyl sulfoxide

CAS:67-68-5 |

|

|

Bis-tris methane

CAS:6976-37-0 |

|

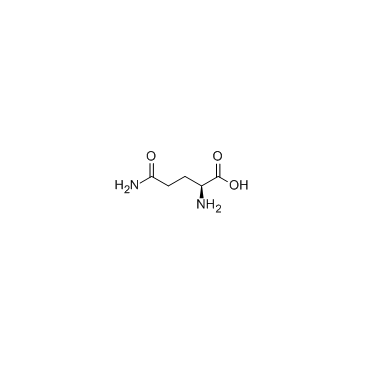

|

L-Glutamine

CAS:56-85-9 |

|

|

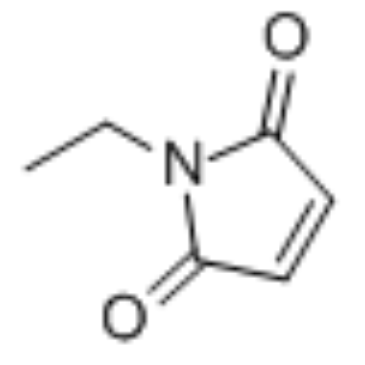

N-ethylmaleimide

CAS:128-53-0 |

|

|

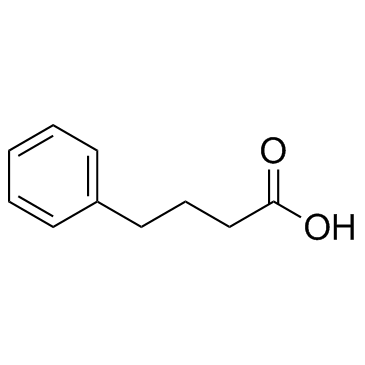

4-Phenylbutyric acid

CAS:1821-12-1 |

|

|

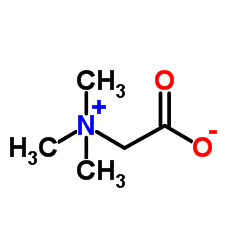

Betaine

CAS:107-43-7 |

|

|

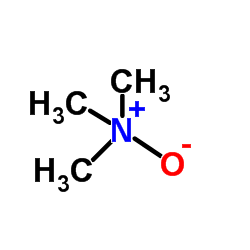

Trimethylamine oxide

CAS:1184-78-7 |

|

|

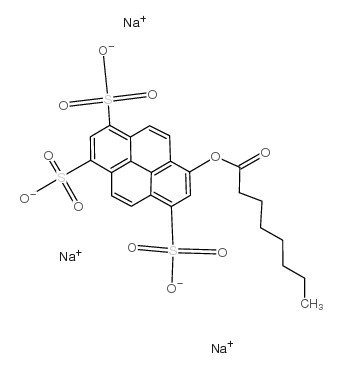

8-Octanoyloxypyrene-1,3,6-trisulfonic acid trisodium salt

CAS:115787-84-3 |