| Structure | Name/CAS No. | Articles |

|---|---|---|

|

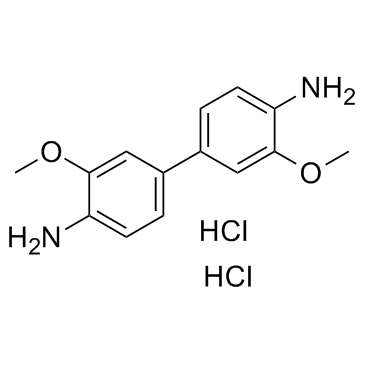

3,3'-Dimethoxybenzidine dihydrochloride

CAS:20325-40-0 |

|

|

sucrose

CAS:57-50-1 |

|

|

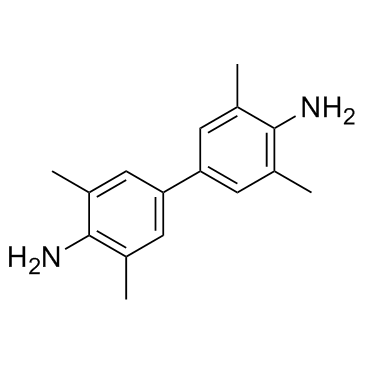

Tetramethylbenzidine

CAS:54827-17-7 |

|

|

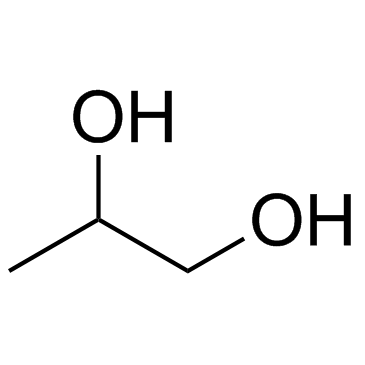

Propylene Glycol

CAS:57-55-6 |

|

|

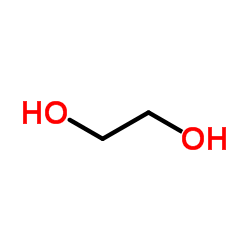

Ethylene glycol

CAS:107-21-1 |

|

|

Furfuryl alcohol

CAS:98-00-0 |