| Structure | Name/CAS No. | Articles |

|---|---|---|

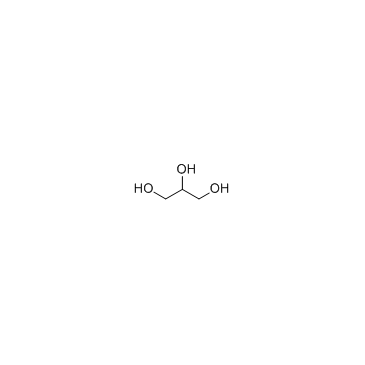

|

Glycerol

CAS:56-81-5 |

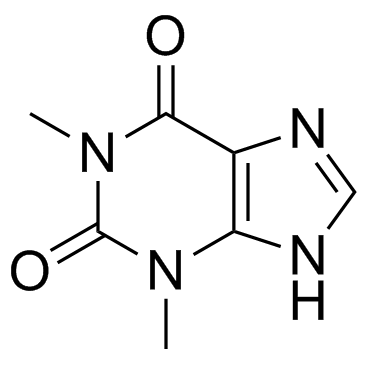

|

|

Theophylline

CAS:58-55-9 |