| 结构式 | 名称/CAS号 | 全部文献 |

|---|---|---|

|

蔗糖

CAS:57-50-1 |

|

|

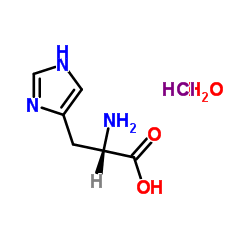

L-组氨酸盐酸盐,一水

CAS:5934-29-2 |

| 结构式 | 名称/CAS号 | 全部文献 |

|---|---|---|

|

蔗糖

CAS:57-50-1 |

|

|

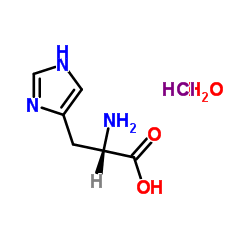

L-组氨酸盐酸盐,一水

CAS:5934-29-2 |