Influence of Texture and Grain Refinement on the Mechanical Behavior of AA2219 Fabricated by High Shear Solid State Material Deposition

O.G. Rivera, P.G. Allison, L.N. Brewer, O.L. Rodriguez, J.B. Jordon, T. Liu, W.R. Whittington, R.L. Martens, Z. McClelland, C.J.T. Mason, L. Garcia, J.Q. Su, N. Hardwick

文献索引:10.1016/j.msea.2018.03.088

全文:HTML全文

摘要

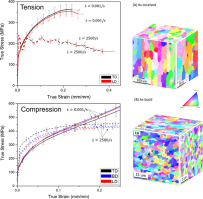

Issues with rapid grain growth, hot cracking and poor ductility have hindered the additive manufacturing and repair of aluminum alloys. Therefore, this is the first investigation to spatially correlate the processing-structure-property relations of a precipitation hardened aluminum alloy 2219 (AA2219) material with respect to deposition orientations and build layers. The AA2219 material was processed by a high deposition rate (1000 cm3/hr) solid-state additive deposition process known as Additive Friction Stir Deposition or MELD. An equiaxed grain morphology was observed in the three orientations, where Electron Backscatter Diffraction (EBSD) identified a layer-dependent texture with a strong torsional fiber A texture in the top of the build transitioning to weaker textures in the middle and bottom layers. Interestingly, the tensile behavior reflected the texture layer-dependence with tensile strength increasing from the bottom to the top of the deposition. However, there were no statistically significant differences in hardness measured from the top to the bottom of the deposition. Furthermore, no orientation dependence on mechanical properties was observed for compression and tension specimens tested at quasi-static (0.001/s) and high (1500/s) strain rate. Transmission Electron Microscopy (TEM) determined a lack of θ’ precipitates in the as-deposited cross-section, therefore resulting in no precipitation strengthening.

|

Microstructural evolution and improvement in mechanical prop...

2018-04-10 [10.1016/j.msea.2018.04.031] |

|

Effect of layered microstructure on the superplasticity of f...

2018-04-07 [10.1016/j.msea.2018.04.028] |

|

Metallic glass hardening after thermoplastic forming

2018-04-07 [10.1016/j.msea.2018.04.021] |

|

Strain rate sensitivity assessment of metallic materials by ...

2018-04-07 [10.1016/j.msea.2018.04.023] |

|

Detection of Intergranular Embrittlement of Reactor Pressure...

2018-04-04 [10.1016/j.msea.2018.04.008] |