| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Water

CAS:7732-18-5 |

|

|

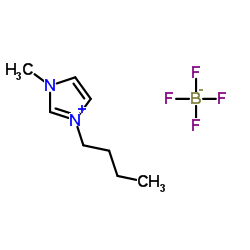

1-Butyl-3-methylimidazolium tetrafluoroborate

CAS:174501-65-6 |