| Structure | Name/CAS No. | Articles |

|---|---|---|

|

Zinc sulfide

CAS:1314-98-3 |

|

|

cadmium selenide

CAS:1306-24-7 |

|

|

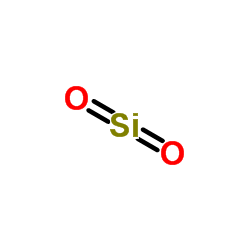

Silicon dioxide

CAS:7631-86-9 |