| Structure | Name/CAS No. | Articles |

|---|---|---|

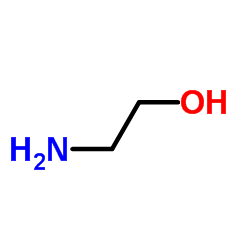

|

2-Aminoethanol

CAS:141-43-5 |

|

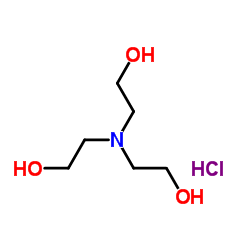

|

TRIETHANOLAMINE HYDROCHLORIDE

CAS:637-39-8 |

|

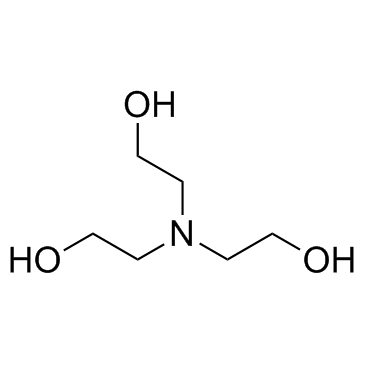

|

Triethanolamine

CAS:102-71-6 |