| Structure | Name/CAS No. | Articles |

|---|---|---|

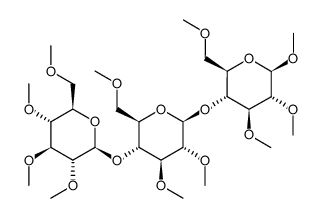

|

methyl cellulose

CAS:9004-67-5 |

|

|

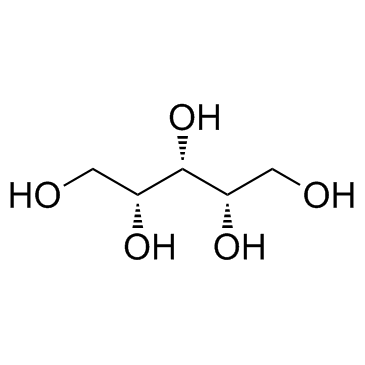

Xylitol

CAS:87-99-0 |

|

|

Dicalcium phosphate

CAS:7757-93-9 |

|

|

Hydroxypropyl Methyl Cellulose

CAS:9004-65-3 |

|

|

Lactose

CAS:63-42-3 |