Thermal conversion of aspen wood in supercritical ethanol in the presence of high-silica zeolite catalysts

B.N. Kuznetsov, V.I. Sharypov, N.G. Beregovtsova, S.V. Baryshnikov, A.V. Pestunov, А.V. Vosmerikov, L. Djakovitch

Index: 10.1016/j.jaap.2018.01.022

Full Text: HTML

Abstract

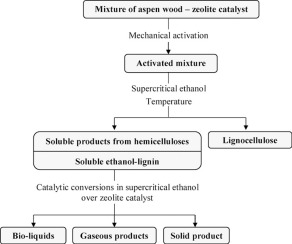

The use of high-silica zeolite catalysts and the preliminary mechanical treatment of aspen wood increase the wood conversion in supercritical ethanol at temperatures 270 and 350 °C and rise the yield of resulting liquid products. The suggested mechanism of aspen-wood conversion over solid catalysts includes the steps of thermal dissolution of native wood lignin in supercritical ethanol and its further catalytic conversions to liquid hydrocarbons. At temperature 270 °C and pressure 6.4 MPa zeolite catalysts increase by 2.3–2.5 times the yield of liquid products with b.p. < 180 °C and the content of furan derivatives (mainly furfural and 5-HMF) in ethanol soluble products. The highest activity demonstrates the catalyst H-HSZ-30 with Si/Al = 30, which has the most high concentration of acidic sites. The rise of a pressure from 6 to 17 MPa at 270 °C increases 2 times the yield of fraction with b.p. > 180 °C (to 63 wt.%) and reduces the yield of fraction with b.p. < 180 °C. The increase a temperature of aspen wood catalytic conversion in supercritical ethanol to 350 °C decreases the yield of liquid products and initiates the secondary reactions of liquid components transformation to gaseous and char products. Thus, the conversion of mechanically activated mixture of aspen wood and zeolite catalysts in supercritical ethanol at 270 °C allows to separate the biomass components on liquid products from hemicelluloses and solid lignocellulose. At temperature of wood catalytic conversion 350 °C mainly the liquids from polysaccharides and lignin are formed along with gaseous and char products.

|

Distribution of PCDD/Fs over the three product phases in wet...

2018-04-10 [10.1016/j.jaap.2018.04.005] |

|

Evolution of sulfur during fast pyrolysis of sulfonated Kraf...

2018-04-09 [10.1016/j.jaap.2018.04.006] |

|

Study of the thermal behavior, kinetics, and product charact...

2018-04-07 [10.1016/j.jaap.2018.04.001] |

|

Ni-doped high silica HZSM-5 zeolite (Si/Al = 200) nanocataly...

2018-04-05 [10.1016/j.jaap.2018.04.003] |

|

Coupling pyrolysis with mid-infrared spectroscopy (Py-MIRS) ...

2018-04-04 [10.1016/j.jaap.2018.04.004] |